Fadal CNC 88, CNC 88HS and MP-32

Cable Connections

We have successfully used the connection details below.

Machine End Pin No

DB 25 connector

|

Computer End Pin No

DB 9 connector

|

|

1*

|

Do NOT connect

|

|

2

|

2

|

|

3

|

3

|

|

7

|

5

|

|

4 and 5 linked together

|

|

*There should be an uninsulated wire between the outer jacket and the foil shield.

Connect this wire to pin 1 at the machine end only. Never connect to pin 1 at both

ends or a ground loop can occur.

Machine Parameters

Strictly speaking it is is not necessary to change any parameters. All that needs

configuring is the Baud Rate. This can be changed by using the CD command, but this

change is not retained on power off.

To change using the CD command:

Press the manual key until the ENTER NEXT COMMAND prompt is showing and enter CD,

followed by a number listed below that represents the required baud rate. For example

CD,8 would set the baud rate at 9600.

|

Value

|

Baud Rate

|

|

1

|

110

|

|

2

|

150

|

|

3

|

300

|

|

4

|

600

|

|

5

|

1200

|

|

6

|

2400

|

|

7

|

4800

|

|

8

|

9600

|

|

9

|

19200

|

|

10

|

38400

|

To change using the machine parameters

To change the baud rate so it is retained on power off. Press the manual key until

the ENTER NEXT COMMAND prompt is showing and enter SETP. Press ENTER until the Baud

Rate parameter is selected. Key in a number from the above table and then press

the ENTER key. Press MANUAL to exit the parameters.

Other Settings

All Fadal controls have the settings detailed below. These are fixed and cannot

be changed with the machine parameters.

|

Hand Shaking

|

XOn/XOff

|

|

Parity

|

Even

|

|

Data Bits

|

7

|

|

Stop Bits

|

1

|

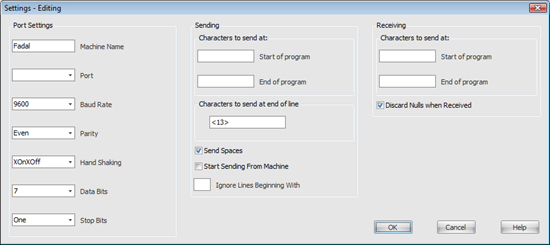

SharpEdit Settings:

How to send and receive

Sending to machine

- At the machine, press the manual key until the ENTER NEXT COMMAND prompt is showing.

- Enter TA,1.

- At SharpEdit press the

button to send the Nc code.

button to send the Nc code.

The Fadal control supports

Start Sending From Machine. With this checked

you are able to press the

button first and then go to the machine and enter TA,1 and the sending will be initiated

at the PC.

Receiving from machine

- At SharpEdit press the

button and SharpEdit will be waiting to receive.

button and SharpEdit will be waiting to receive.

- At the machine press the manual key until the ENTER NEXT COMMAND prompt is showing.

- Enter PU,2.

- At SharpEdit, when Bytes Received has stopped increasing, press the Finished button.

There are different values that can be used with the PU command listed below:

|

Value

|

Description

|

|

0

|

Program, tool and fixture data

|

|

1

|

Tool and fixture data only

|

|

2

|

Program only

|

|

3

|

All programs in memory

|

DNC Operation

If you want to drip feed the Nc code to the machine because it is to large for the

memory.

- At the machine press the manual key until the ENTER NEXT COMMAND prompt is showing

and enter DNC.

- At SharpEdit press the

send the Nc code.

send the Nc code.

- Press the cycle start button at the machine.

To send a program using the DNC command, it must NOT contain a program number or

any comments.